Titanium is a metal found in many products used and consumed on a daily basis. It is the most corrosion-resistant, lightest, strongest, and hardest metal there is. With these properties, the metal has found particular applications in aerospace and biomedical engineering, among other fields. This is even as its uses become more diverse to help with the modernization of the society.

The Process of Making Titanium Bars

In order to make a titanium bar, the manufacturers use casting and rolling processes. The solution of the alloying elements of titanium and aluminum are mixed through a melting process. Then it is poured into ingots and heated up to 600 degrees Celsius in an oven before being rolled out with a roller to form the bar shape.

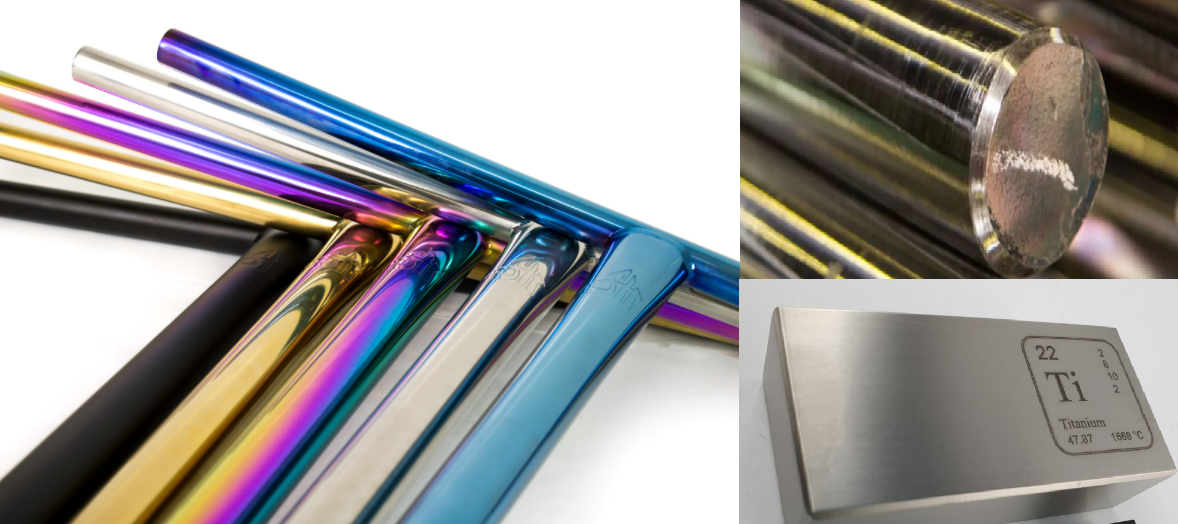

There are two types of titanium bars: flat-rolled and round-rolled bars. Flat-rolled bars are made by cutting multiple layers of sheets into single pieces and then rolling them into a bar. Round-rolled bars are made by rolling the sheets continuously without interruption through a series of rolls with a diameter larger than the finished bar size.

Titanium is also a hard, lustrous, and highly corrosion-resistant silver-white transition metal with a low density and extremely strong. The metal can be cast into thin sheets, rolled into long tubes (tubes are the most common form of titanium), and forged into long rods.

The key to a standard product in a metal manufacturing process is always following the right procedure from the raw materials to the finished products. For instance, with titanium, its standard can only be gauged from the light, strong, and highly corrosion-resistant features.

However, titanium is a very difficult metal to process and manufacture, so it requires a complicated manufacturing process. This also explains its expensive prices.

Manufacturers Quality Check on Titanium Bars

In order to check the quality of the bars, manufacturers need to use specialized machineries such as corrosion and magnetic particle testers. These testers are used to detect any inconsistencies in the material that could cause issues later on.

Being one of the most durable metals that is used in manufacturing. Manufacturers use a process called magnetic particle testing, which allows them to check the quality of a titanium bar.

Magnetic particle testing, also known as magnetism test, measures the quality of metals by detecting magnetic or paramagnetic particles in the samples.

This process uses a low-power electromagnetic field with an alternating current and voltage that oscillates at 50 Hz and 1 kHz to produce a magnetic field. The sample is placed within the magnetic field, and particles are attracted to it depending on their properties, such as size and shape.

What to Look for Before Making Titanium Bar Purchases?

Titanium is a metal with many uses, but it can be quite expensive. You need to consider the material properties of titanium and decide whether it is worth the price or not.

The bars also come in various shapes and sizes. Depending on the shape, the company might use different manufacturing processes to create them. You, therefore, need to be sure about how you aim to use the bars before selecting an already manufactured bar or before placing your order.

The price of titanium bar is what tends to scare most people off. However, based on your intended applications, you can find the best deals from HeleTitanium manufacturers.