The first-ever 3D printing was all the way back in the early 1980s, but like many new inventions, it took years for 3D printing to evolve into the phenomenon it is today. Now, 3D printers are in use in almost every major field for manufacturing as well as educational purposes. The biggest reason why 3d printing is so popular nowadays is the speed.

One of the primary purposes of 3D printing was to help speed up the process of prototyping. Before 3D printing, companies would spend hundreds of dollars on prototypes only to end up making some final tweaks and having to redo everything. 3D printers now help save a lot of time and money in the name of prototyping.

With the technological advancements, 3D printers have now come far from just a prototype-making machine. Now, 3D printers are available in schools, colleges, hospitals, and large-scale manufacturers for all sorts of applications.

In this article, we will take a look at the different applications of 3D printing and how 3D printers are in use in various industries for various purposes. We will be focusing on industrial applications of 3D printing other than prototyping and manufacturing.

Aerospace And Defence

One of the first-ever industrial applications of 3D printing was in the Aerospace and Defence industry. The additive manufacturing process has now become an integral part of the Aerospace and Defence industry. The A&D industry now not only applies various 3D printing technologies but they are also a major player in new research and development on this manufacturing process.

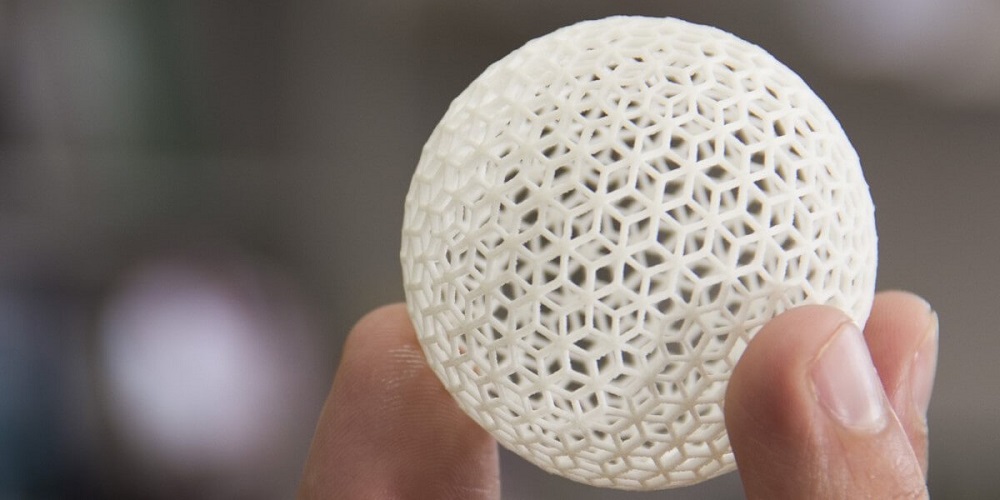

The A&D industry majorly uses 3D printing for making prototypes, tools, and even some integral parts of aircraft, vehicles, and a lot more. Making various small parts of an aircraft using plastic and 3D printing allows the manufacturers to reduce the weight of their equipment while keeping the functionality the same.

Some of the biggest ammunition manufacturers are using 3D printing to improve their design and manufacturing of small rockets for fighter jets and helicopters. Not to mention the flexibility 3D printing has brought to the production of spare parts of aircraft, tanks, trucks, and every military and civilian vehicle. The same goes for the automobile industry too.

Medical Applications

A relatively newer adapter of 3D printing, but the medical industry is really exploiting the wide range of applications of 3D printing. From printing prosthetic limbs to printing aluminum bones, there are various cases around the globe of how 3D printing is not only saving lives but changing them for the better.

Even from manufacturing medical equipment like MRI machines to small devices like hearing aids, 3D printing is everywhere. Even in the dental field, the use of 3D printing has drastically improved dental implantology. Dentists are now able to create crowns, bridges, and even teeth exactly according to the patient’s needs, and it is cheaper too.

The next big step for 3D printing in the medical field is Bioprinting which helps doctors create prosthetic tissue that does the job just as well as our tissues. However, it still needs time and work to reach its full potential.

Consumer Applications

Perhaps the biggest winner from the rise of 3D printing has been the consumer goods industry. We are talking about cell phone manufacturers, laptop manufacturers, house electronics, children’s toys; 3D printing has been a blessing for all these industries.

By using 3D printers for making the majority of their equipment, these industries have not only sped up the whole manufacturing process but also end up saving a lot of money and making a lot of profits. 3D printing is a primary reason why brands like Samsung and Apple can release such good devices every year.

Apart from the major player that is the electronic industry, other smaller industries like footwear, fashion, and cosmetics are also reaping the benefits of the application of 3D printing in their manufacturing processes.