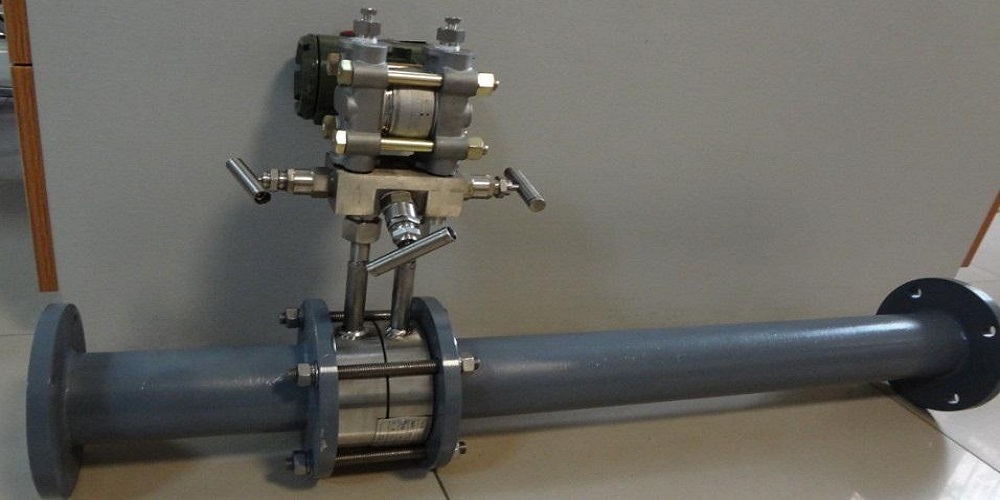

An orifice flow plate meter is a device that measures the steam, gas, & liquid flow that we use in a controlled process. This device is made up of a differential pressure transmitter, sensors, and flow totalizer.

This instrument has wide applications in electric power, chemical industries, heating, petroleum, & metallurgy fields. The working accuracy of the orifice plate meter depends on many factors, and here we are going to discuss some of them briefly.

Let’s get started.

1. Circulation Of Cross-Sectional Area

Due to long-term use, impurities and dirt might get stuck on the orifice place surface that is reducing the cross-sectional flow area. The pressure will increase in the results of circulation area reduction that cause an increase in measurement flow. Make sure to clean the holes properly to minimize the power use and accurate results.

2. Pulsating Flow In Airflow

Pulsating flow has been caused by the abrupt change of pressure & gas velocity in the pipelines. This pulsating flow causes variation of the differential pressure. Big errors can cause due to the pulsation & the modern flowmeters make it more complicated.

3. Instrument Performance

In most cases, one of the basic accuracy errors is caused by the instrument itself. The sharpness of the right angle, controlled accessories, thickness error, and many other factors need to consider before starting the process. The reliability of the process is determined by the manufacturing quality and principle of the instrument.

The accuracy of the orifice meter can be disturbed by various factors like density & viscosity of the fluid and other changes in them. Before running the device, check all the possible details to avoid disturbance.

4. Environmental Conditions

Many hardware aspects & performance parameters of the flow meter are greatly influenced by the environmental condition. These environmental conditions affect the measurements & accuracy of the flow meter.

Various conditions like fluid contamination, corrosion, & environmental temperature can cause errors in the long-term use of machinery. That’s why the flow measurement system installation has strict technical requirements to minimize installation errors.

5. Measured Fluid Characteristics

Due to the presence of natural gas in the system, any change in the outside temperature greatly affects the gas nature, which indirectly affects the flow meter accuracy. For natural gas flow measurements, it is very important to determine the working pressure and temperature to get predictions about possible changes. Keep in mind that the temperature changes gas pressure.

In most cases, low-density gases cause problems for some methods. In such cases, you need to change the selected method for pressure and temperature correction for accurate results.

The orifice plate meter plays an important role in the flow measurement of the flow meter. It is not easy to get a product that will meet all your requirements. Shanghai Wan Hui Machinery Co., Ltd is a China-based Machinery parts Manufacturer Company. This company is supplying its products in varied price ranges with amazing customer services. Click on https://www.whmcn.com/products/flow-conditioner/ to have a look at available products & place your order.