Many people have tried cnc machining aluminum without getting it right, and there is only one reason – not knowing how it works. When CNC machines were newly created, it was only the big companies that owned the machines. This happened because the small and medium companies could not afford to buy a CNC machine. However, the story has changed, and CNC machines are now largely available to whoever needs them. These machines are amazing at speeding up production processes and reducing the risks involved in using a device. Also, there has been an evolution as to the type of CNC machines available globally. There are now different types of CNC machines, each having a specific purpose. The function of the CNC machine is the primary determinant of what you can use it for. CNC machines reduce mistakes you will make when there is human involvement in handling machines. With CNC machines, you’re not bothered about someone getting injured because the operator uses programs to control the device.

There is no need for physical touch to use a CNC machine for aluminum. All the physical touch necessary has been done when the machine was created. After the manufacturing of the device, the machine depends on computer-aided programs to keep it running. The first computerized program is the design segment of the machine, where the CNC machine designs what you want. You see the design you are producing in its clearest form, as it comes as a 3D design. If there are any changes in the design, you will notice easily and effect the changes. After effecting the changes, the design phase is over, leaving only the production. Once the design is okay, the programs command the CNC machine to start production, and it does this without your help. But it can be confusing how the CNC machine works. Sometimes, even the operator using programs to command the machine can’t exactly tell how it works. The CNC machine operates based on amazing parts of the machine. Each of the parts has their specific purpose, and they are codependent on each other. In this guide, we will be discussing each part of the CNC machine and how they contribute to the working process of the machine.

Control Panel

As the name implies, the control panel of the CNC machine is responsible for all activities. This is the part of the machine that the operator is working with. It is from this part that every other part works. With the control panel, you can give commands, edit some, and alter all the processes of the CNC machine.

Pedal

The part of the machine controlling all processes is the Pedal. It is the part of the machine that gets the command to grip the item to cut or build.

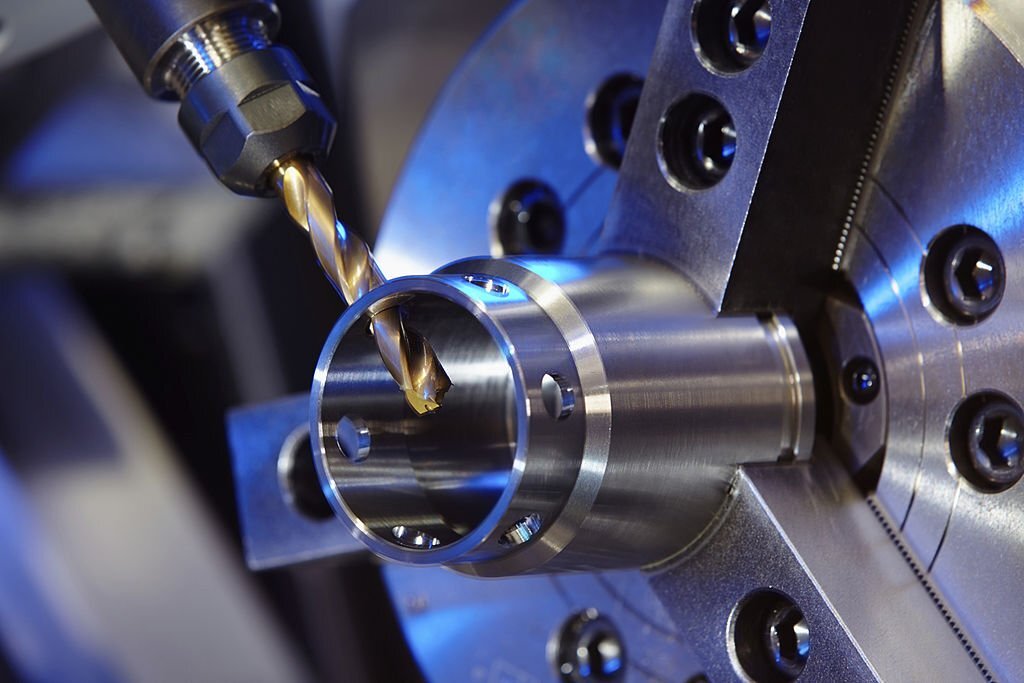

Tool turret

When you are building with a CNC machine, you may have the most complex of shapes to build. The tool turret is responsible for the various shapes. It is the part that acts as the base for the shaping of materials.

Bed

As against what you may think, the bed of the CNC machine is the hardest part. This part has a high resistance to any form of wear and tear.