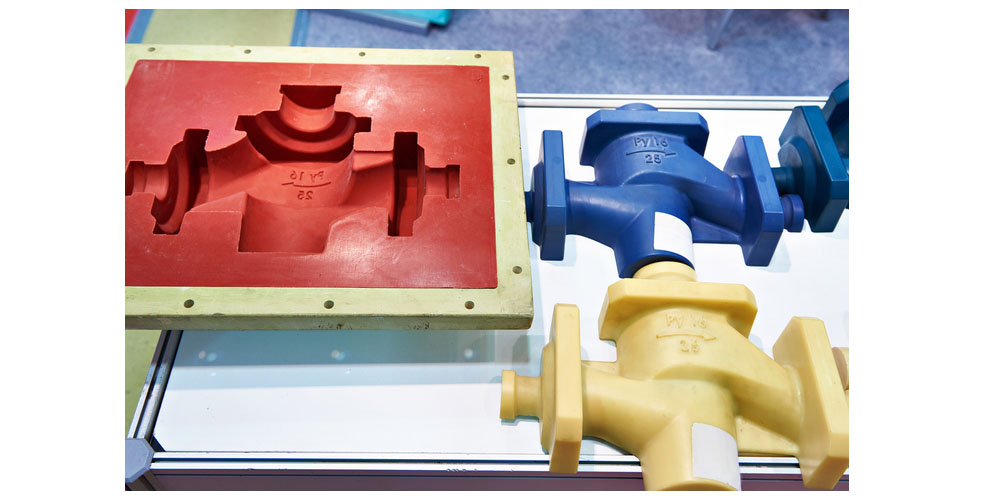

Urethane casting is a manufacturing process that produces models of low or medium volume. Soft tooling is used to create more flexible parts compared to other methods. The manufacturer creates a silicone mold that mimics the final product and fills it with Urethane resin to cure. Once cooled, the part is removed, set aside, the mold is refilled, and the process continues. Urethane casting is suitable for creating up to 25 parts; it has excellent versatility and many other advantages. We look at the Urethane casting benefits below.

Benefits of Urethane Casting Process

Urethane casting is much better than other plastic-producing methods such as 3d printing and injection molding. Some reasons for this include;

1. High speed of production

The process is fast, unlike in injection molding, because low volume production of prototypes takes place. Manufacturing a few parts using injection molding is not worth the investment; hence, Urethane casting is good. Also, the silicone molds in Urethane casting are made very fast since the tooling used is soft compared to metal. The high speed also makes it a bridging process. This is when parts are needed immediately, so they are developed before the hard tooling in injection molding is created. Customers using urethane casting remain competitive since the parts are introduced to the market within a short time since production.

2. Produces high-quality parts

Production is done with high precision to create form parts of different shapes and sizes. Manufacturers use different materials that contribute to the rubbery nature of these parts and also give them a transparent or colored appearance. The cast Urethane process forms parts with similar or better properties than those in injection molding. Their physical properties are also better than parts made from 3D printing. Despite these parts being between rigid and flexible, they are strong enough for use in various applications.

3. Reduced costs

Generally, cast Urethane is cheaper than traditional methods and other modern manufacturing processes. The resin poured into the mold is bought at a low price, and also, making the silicone mold doesn’t require much money. So much money is spent in developing hard tooling in the injection molding process. In addition, the urethane casting method allows you to have good quality items at an affordable price which is usually not the case for others.

4. Increased Flexibility

Urethane casting incorporates several materials for the production of parts. The silicone resin is soft and highly flexible, making it easy to form a mold. The mold, which is a representation of the final part, can assume any shape or angle. The flexibility allows designers to use more features on the parts and stop the use of over molds, undercuts, and expensive slides. After curing, it’s easy to eject the parts from the mold without causing any damage. In addition, if the part goes through product testing and fails, changing the design is quick and easy than rigid parts.

Final word

Urethane casting is also known for its smooth finish on parts. It is fast, affordable, and efficient, making it useful in production and is beneficial for all applications. It’s also a good choice for the continuous flow of parts in the market since the lead production time is short. Maximize cast Urethane advantages by choosing a skilled and experienced manufacturer to produce your goods.