Prototyping popularity has grown tremendously recently. The popularity is because of the numerous benefits that it accrues to various industries in the economy. The growth in popularity has encouraged the existence of many manufacturers in the market. The many manufacturers in the market all share the same functions. Furthermore, some like Rapid Prototyping China offer global services. Thus, this article aims to inform you of the five functions of Prototype manufacturing companies.

5 functions of Prototype manufacturing companies

1. Testing and evaluation

One of the essential functions of prototype manufacturing companies is testing and evaluation. The prototype manufacturing companies are charged with testing whether prototypes developed are feasible for the market. They also test whether the prototype is effective, thus viewing whether the final product will be effective. Furthermore, the companies evaluate the viability of a part in the current world, like in the political, economic, or social context.

Additionally, the prototype manufacturing companies evaluate whether primary stakeholders will support a prototype and whether it is scalable for massive impacts. Therefore, prototype manufacturing companies test and assess all facets of a prototype to ensure that all stakeholders approve.

2. Design practice

Prototype manufacturing companies manufacture prototypes that can be used for design practice. Furthermore, some manufacturers may allow for the use of different designs to create prototypes. Each design will have its characteristics or look for how the final design will resemble. Thus, the client can decide on which prototype feels and looks better before mass production.

3. Ensure ready parts for investor pitches

One of the best functions of prototype manufacturing companies is that they allow clients to use the prototypes for investor pitches. The most common type of prototype used in establishing investor pitches is the medical prototype. The prototype allows one to demonstrate how the final product will work, its benefits, and its properties. Thus, clients can use prototypes to request investor funding before mass production takes place.

4. Ensure patenting approval

Prototypes are generally not required for patenting. But, they help increase the chances of patent approval. Thus, prototype manufacturing companies ensure that the prototype manufacturers are working well. The purpose of this is to ensure that one’s idea is fully explained aside from the use of drawings. A working patent will ensure that one’s business has a higher chance of receiving a patent for its product. Furthermore, patent laws need for the patent application process to be as detailed as possible. Thus, a prototype manufacturing company has to ensure that all the parts are working smoothly.

5. Giving life to ideas

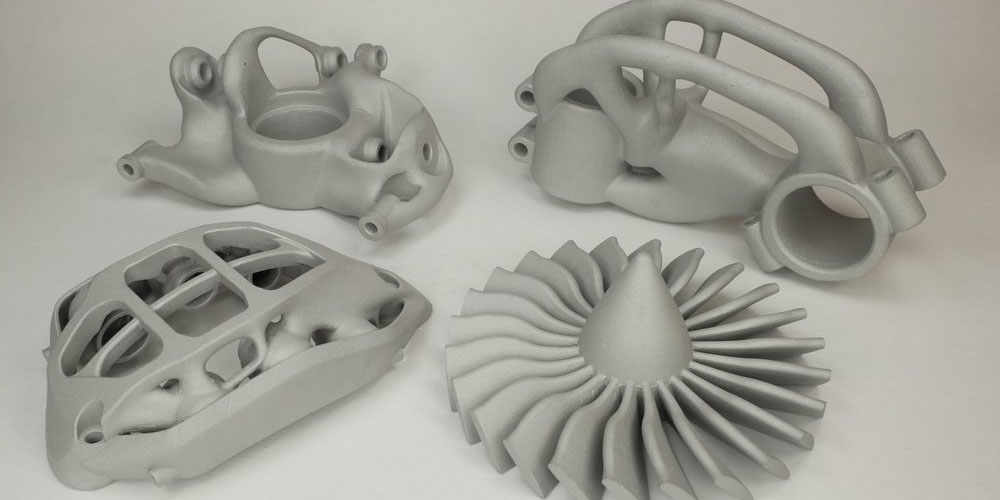

Prototype manufacturing companies use 3D drawings to give life to ideas. For example, when one holds apart, they can better understand the functionality and appearance. Furthermore, the manufacturing companies help to transform your ideas and designs into workable parts. Additionally, in some prototyping services like the 3D, one can simulate the design, ensuring they can make corrections where possible to ensure functionality.

Conclusion

There are many functions involving prototype manufacturing companies. But, the most common function is to ensure that prototypes produced are quality and can function correctly. Thus, while acquiring the services of prototype manufacturing companies, it is crucial to know all the roles they play in ensuring quality parts.